ReportLinker’s learning algorithm trained for MI provides Intelligent market insights to determine the causes and effects of the global semi conductor shortage:

- What are the key drivers behind the shortage?

- Which countries and players have been impacted the most ?

- What is being done by companies and governments to prevent a recurrence ?

Get all the answers.

What are the key drivers behind the shortage?

Monitoring the latest news, it is estimated that the global semiconductor sector is suffering a serious shortage that is expected to last well into 2022 and into 2023 [1]

Figure 1

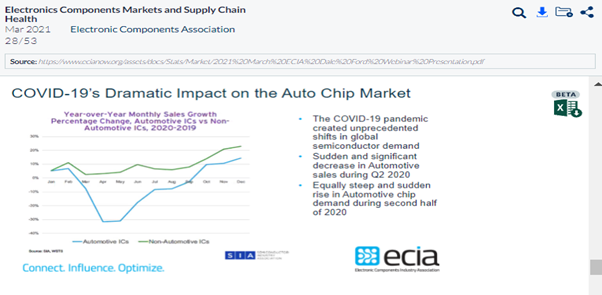

Looking at the latest trends in the semiconductor industry, we can see that the main reasons for the shortage as of October 2021 are a combination of factors from hoarding [2], ramping up demand coming from economic recovery [3] and supply chain constraints among other factors.

Figure 2

Figure 2

Figure 3

Market structure as a cause of the shortage : an overdependence on Taiwan

Who are the leading players in the industry? Which countries dominate the market? Find out using ReportLinker’s smart research tools and trackers.

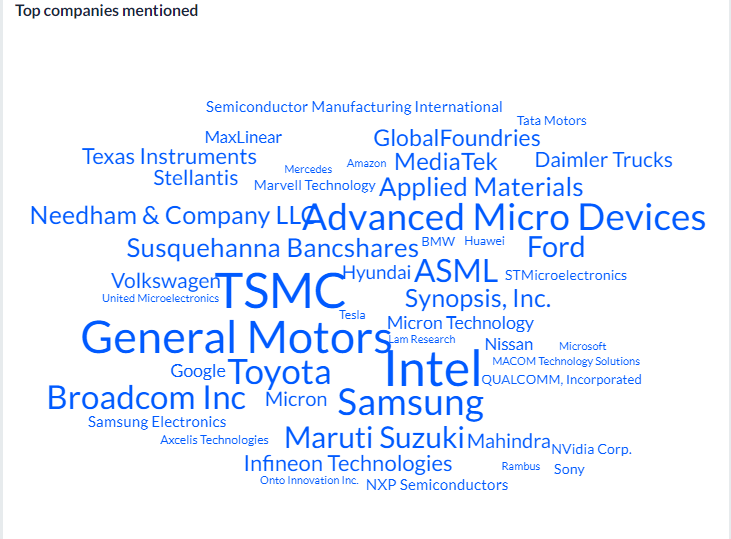

Company Analytics to understand the market

The AI-enabled company analytics tool enables you to quickly identify the companies most cited across the content previously selected using ReportLinker’s NLP filters, as seen in Figure 4.

Figure 4. The companies most cited in reference to the global chip crunch

Not surprisingly TSMC, Intel, and Samsung are emerging as the key players of the sector.

Industry Analysis

Industry analysis reports provide an in-depth understanding of the sector, providing insights of the over-dependence on Asian manufacturers to prevent future shortages, as seen in Figure 5 below.

Figure 5. Taiwan semiconductor manufacturing company accounts for 54% of global revenue

Figure 5. Taiwan semiconductor manufacturing company accounts for 54% of global revenue

ReportLinker also provides access to comprehensive graphs embedded within reports using the search tool. Figure 6 shows one such report highlighting Asia’s dominance when it comes to chip manufacturing.

Figure 6. Global chip manufacturing trends by geography

What is being done by companies and governments to prevent a recurrence?

Due to the massive investment required, the industry doesn’t build new chip manufacturing facilities with spare capacity. And with plants currently operating “at over 90 percent capacity utilization and at 100 percent for critical parts,” the semiconductor shortage will continue until new capacity is built.

According to the latest news and Partnerships Insights spotted by our company production & capacity smart insight trackers, Taiwan Semiconductor Manufacturing Co. (TSMC) plans to increase capacities,[7] opening new manufacturing plants in China [8] and establishing new partnerships to expand semiconductors production [9].

Figure 7. TSMC increases capacities.

Figure 8. TSMC invests in expanding chip manufacturing facilities in China

Figure 9. TSMC announces new partnership with Sony

The bottom line

Asia dominates the semiconductor market and will continue to do so in the foreseeable future. The shortage is expected to continue with numerous industries being impacted, including the automotive sector, which is expected to lose 110 billion in sales in 2021.

It is therefore key to monitor the market dynamics as the situation unfolds, to make data driven decisions.

Pooling vast amounts of information and intelligent, AI-based search tools, ReportLinker delivers up-to-date, in depth insights for better, more informed decision making.